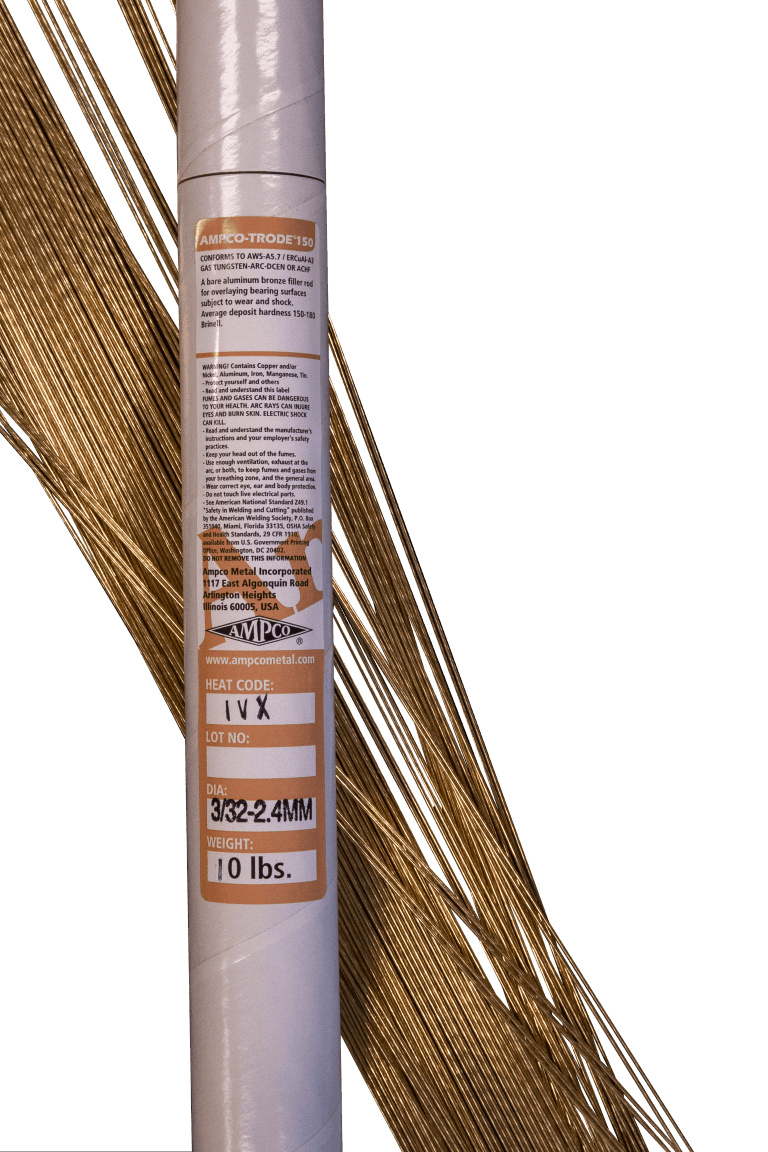

AMPCO-TRODE® 150

AWS A5.7 – ERCUAL-A3

Description and Application

AMPCO-TRODE® 150 aluminum bronze spooled wire and bare filler rod produce a deposit of high strength and good ductility with a nominal hardness of 166 Brinell as applied with the inert-gas processes.

AMPCO-TRODE® 150 is recommended for welding AMPCO® 18 alloy. It is ideal for piston overlay applications and bearing surfaces requiring high strength and good ductility.

Typical Applications

| Hydraulic pistons | Bearing overlays | Impellers |

| Turbine runners | Press rams | Cable sheaves |

| Mill slippers | Valve seats and parts | Breaker blocks |

| Ceiling machine mandrels | Steel mill rolls | Welding AMPCO® 18 |

AMPCO-TRODE® 150

| Limiting Chemical Composition | |

| % (filler metal) | |

| Copper* | Balance |

| Aluminum | 10.0 – 11.50 |

| Iron | 2.0 – 4.50 |

| Silicon | 0.10 max. |

| Others | 0.50 max. |

| * including silver |

| Mechanical Properties | |

| (Nominal all-weld metal values) | |

| Tensile Strength ksi | 90 (621 MPa) |

| Yield Strength ksi | 40 (276 MPa) |

| Elongation % in 2″ (51 mm) | 20 |

| Reduction of Area % BHN (3000kg.) | 22 |

| Hardness (HBW 10/3000) on 1/4″ (6.4mm) deposit | 166 |

Specifications

AWS A5.7 Class ER CuAl-A3

*Hardness will vary depending on quality of the weld and experience and knowhow of the welder.